This post is brought to you by WAGO.

Part 4 of 4

As long as the surfaces are clean and free of oxides at the time of wire insertion (low voltage signals can’t “punch through” oxidation), the gas tight nature of CAGE CLAMP® will maintain the connection quality.

As long as the surfaces are clean and free of oxides at the time of wire insertion (low voltage signals can’t “punch through” oxidation), the gas tight nature of CAGE CLAMP® will maintain the connection quality.

The CAGE CLAMP® system has also been used with excellent results for thermocouple connections.

Unlike most screw-type terminal blocks, CAGE CLAMP® connections do not require checking or retightening the loose connections resulting from vibration, temperature cycling, settling strands, etc.

The built-in reliability of CAGE CLAMP® can reduce downtime and service calls for the customer. Most service departments estimate that 35-50% of all service calls are the result of poor connections. Considering the high cost of service calls and the loss of production time, the savings can be significant.

WAGO offers a complete line of CAGE CLAMP® products. From chassis mount terminal strips to an extensive range of printed circuit board blocks with pin spacings as small as one tenth inch. Standard or custom component plugs, relay sockets and interface modules are also available.

WAGO offers a complete line of CAGE CLAMP® products. From chassis mount terminal strips to an extensive range of printed circuit board blocks with pin spacings as small as one tenth inch. Standard or custom component plugs, relay sockets and interface modules are also available.

Besides the well known agencies of UL and CSA, WAGO products have passed the extensive tests of various agencies throughout the world. This is especially important to export manufacturers.

Besides the well known agencies of UL and CSA, WAGO products have passed the extensive tests of various agencies throughout the world. This is especially important to export manufacturers.

The rail-mounted terminal blocks have a fully touchproof construction and accommodate one-piece insulated jumpers.

The rail-mounted terminal blocks have a fully touchproof construction and accommodate one-piece insulated jumpers.

The front-entry series allow both the screwdriver and wire to enter from the top (front) of the block, saving space and simplifying wiring considerably.

The ground block makes an automatic connection to the rail when it is mounted. No center tap screw are required.

The sensor block line allows multiple-wire sensors or components (i.e.: photoelectric, relyas, etc.) to be connected to their own dedicated, multi-level terminal block, allowing high density and easy troubleshooting.

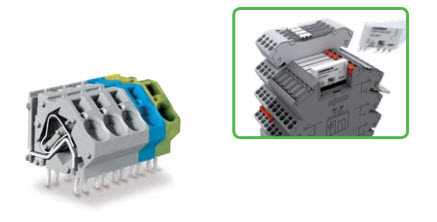

Touch-proof component plugs contain a variety of electronic configurations and plug into front-entry rail mounted blocks. This reduces space, labor and downtime.

Custom marking is economical using WAGO’s marking computer. ProServe software and hardware solutions with the TP-343 Printer.