This post is brought to you by WAGO.

The WAGO CAGE CLAMP®

An Innovation... The rising cost of service calls and a company’s desire to provide more reliable products has changed the way people think about terminal blocks.

In the past, terminal blocks were often thought of as an insignificant part of the overall system, unless you were in field service. Field service technicians say that terminal blocks have always been significant since one of their fist troubleshooting steps is to “check the connections”. They also indicate that connectors are the source of almost half of all system failures.

Checking connections as part of a regular maintenance schedule was the only preventive solution to this problem – until the invention of “CAGE CLAMP®”. CAGE CLAMP® reduces wiring time, eliminates routing maintenance and provides a reliable contact – every time!

CAGE CLAMP® is a unique, patented, stainless steel clamping mechanism designed to automatically connect solid or stranded wire. Various CAGE CLAMP® sizes are available to accommodate wire sizes AWG 28-12. Other than stripping the wire, no special wire preparation such as crimps, ferrules or tinning is necessary.

CAGE CLAMP® is a unique, patented, stainless steel clamping mechanism designed to automatically connect solid or stranded wire. Various CAGE CLAMP® sizes are available to accommodate wire sizes AWG 28-12. Other than stripping the wire, no special wire preparation such as crimps, ferrules or tinning is necessary.

Most screwless systems offered by other manufacturers are based on the leaf-spring principle. This type of connection is found in the back of many electrical outlets. Leaf-spring is only recommended for larger, solid wire since it has no sides to contain the strands and because of the sharp angle in which the wire is contacted.

The CAGE CLAMP® is suitable for:

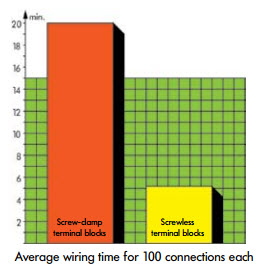

Public wiring competitions and major customer time studies have proven a reduction of wiring time by 75% when comparing manual wiring of screw-type terminals with CAGE CLAMP® terminals.

Even when powered screwdrivers are used for tightening the clamping screws, there is still a time savings advantage for CAGE CLAMP®.

In cases where wire preparation such as crimps, ferrules or tinning can be eliminated, there are additional savings.

Screw connections are “operator-dependent”. In other words, they require judgment on the part of the installer as to the tightness of the screw. This can be somewhat controlled in a factory setting with trained personnel, or with special torque screwdrivers. With field wiring, proper screw connections are more difficult to ensure.

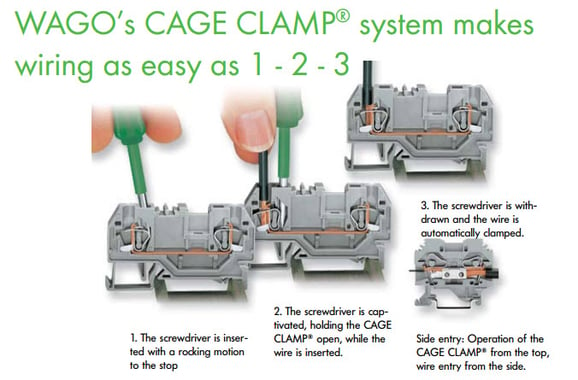

CAGE CLAMP®’s automatic clamping feature allows less skilled labor to make quality connections. CAGE CLAMP® requires no special tools and is operated with a standard straight-bladed screwdriver. Two styles of terminal blocks are available: side-entry and front-entry.

The CAGE CLAMP® is computer designed for maximum reliability. Springs under permanent dynamic load, such as automobile and industrial springs work reliably and perform millions of operations during their lifetime. By comparison, the CAGE CLAMP® is typically operated only a few times and yet it is designed according to the same principles as springs under dynamic load.

The CAGE CLAMP® is computer designed for maximum reliability. Springs under permanent dynamic load, such as automobile and industrial springs work reliably and perform millions of operations during their lifetime. By comparison, the CAGE CLAMP® is typically operated only a few times and yet it is designed according to the same principles as springs under dynamic load.

WAGO has over forty years experience in the design and manufacture of high quality connections. State-of-the-art quality control insures that these high standards are maintained.