This post is brought to you by WAGO.

Part 3 of 4

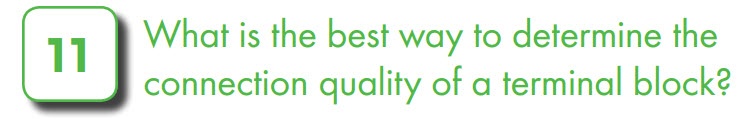

There are two common test methods used in laboratory testing: the voltage drop test and the temperature rise test.

There are two common test methods used in laboratory testing: the voltage drop test and the temperature rise test.

The voltage drop test is useful in determining the resistance of a through connection. It reflects the quality of the clamping point initially, when the wires are first connected, and also while under conditions of vibration, temperature cycling and corrosion.

The temperature rise test is also a reflection of the connection’s resistance. It allows the complete terminal block to be checked at nominal current, high current and short circuit conditions. The CAGE CLAMP® far exceeds the national and agency requirements relating to voltage drop and temperature rise.

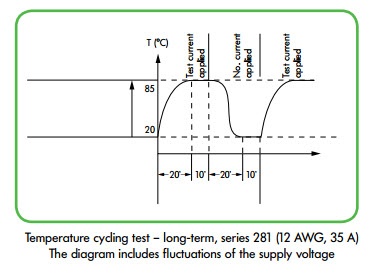

The voltage drop of a connection can change significantly over time, especially when changes in temperature exist. The heating and cooling expand and contract the contact parts, varying the contact pressure and deforming the wire. If this is not compensated for (i.e.: screws tightened) the contact will have a progressively higher voltage drop which can eventually impede the signal or cause arcing.

The voltage drop of a connection can change significantly over time, especially when changes in temperature exist. The heating and cooling expand and contract the contact parts, varying the contact pressure and deforming the wire. If this is not compensated for (i.e.: screws tightened) the contact will have a progressively higher voltage drop which can eventually impede the signal or cause arcing.

CAGE CLAMP® automatically adjust for settling strands and changes in wire size. As illustrated by the results of this temperature cycling test, the voltage drop remains virtually constant – insuring long-term reliability.

The contact materials used in WAGO terminal blocks and connectors are inherently corrosion resistant.

The contact materials used in WAGO terminal blocks and connectors are inherently corrosion resistant.

The stainless-steel CAGE CLAMP® exerts a high specific pressure which embeds the conductors into the soft tin/lead plating of the current bar.

The resulting connection is “gas-tight”, not allowing corrosive gases to penetrate and degrade it.

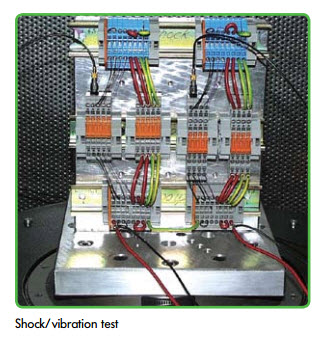

The CAGE CLAMP® itself has very little mass in relation to the high force it produces. The way in which the CAGE CLAMP® is mounted on the current bar insures that a favorable division of masses (of current bar, conductor and CAGE CLAMP®) is obtained. These factors result in a connection which has high resistance to vibration and shock, without wire damage or measurable contact interruption.

The CAGE CLAMP® itself has very little mass in relation to the high force it produces. The way in which the CAGE CLAMP® is mounted on the current bar insures that a favorable division of masses (of current bar, conductor and CAGE CLAMP®) is obtained. These factors result in a connection which has high resistance to vibration and shock, without wire damage or measurable contact interruption.

WAGO has tested CAGE CLAMP® for vibration up to 2000 Hz with accelerations up to 20 G’s. Independent agencies have tested and passed CAGE CLAMP® for shock and vibration up to 2000 Hz with accelerations up to 109 G’s in each of three axes. CAGE CLAMP® also meets the vibration test requirements of VDE 0611 which incorporates a pull test while vibration is present.

The UL “waggle” test also puts a rotational force on the wire while a pullout force is applied.

VDE specifications limit the temperature rise of terminal blocks to 45o Kelvin under continuous load at nominal current. After a current load of 1.6 times the nominal current over a period of one hour, WAGO terminal blocks don’t show any signs of damage.

VDE specifications limit the temperature rise of terminal blocks to 45o Kelvin under continuous load at nominal current. After a current load of 1.6 times the nominal current over a period of one hour, WAGO terminal blocks don’t show any signs of damage.

The short circuit-test according to IEC 17B specifies that 120 A per square mm has to be applied for a period of one second.

CAGE CLAMP® connections pass this test without damage or impairment of their function.

The impractical test shown (a fused circuit would limit such an occurrence) demonstrates the contact capability of CAGE CLAMP®. The current through a 12 AWG terminal block is increased until the conductor glows red. The block remains undamaged.