-

- new product

- WAGO

- thomas

- bimba

- humphrey products

- Dorner Conveyors,

- Epsitron

- IAI

- Norgren

- diaphragm pump

- dorner

- mfd

- thomas 1510

- 005 Series

- 1510

- 2200 Series

- 3014

- 80/20

- Acro

- Analog Input I/O

- Balanced Valves

- Baumer

- Cleanroom Type

- Converters

- ECO Power Supplies

- Encoder

- Extreme Environments

- Humphrey

- IO-link

- L310

- Modbus Couplers

- Modular Belt

- New Module

- Pinch Valve

- ProControl Series

- ProControl Valves

- RCP2

- Robots

- SCARA

- Sensors

- Timer Relay

- Topjob

- XTR

- aluminum extrusion

- compact cylinders

- conveyor

- cylinder

- ethercat

- filters

- flat cylinder

- intelligent actuator

- pneumatic actuators

- pump

- pumps

- regulators

- solution

- solution pump

- terminal blocks

- thomas 1610

- valve

- worlds smallest valve

- yellow powder coat

Get the latest in your inbox.

This post is brought to you by Asyril.

The Asyril flexible feeder family is growing ...

With the arrival of the Largo A5 in its product range, Asyril now offers a wide choice of flexible feeder systems for parts reaching from a few tenths of a millimetre to some twenty millimetres size!

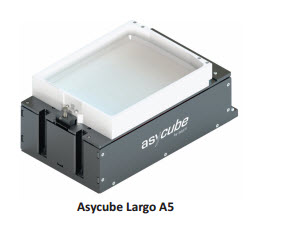

ASYCUBE LARGO A5, THE NEW FEEDER IN THE FAMILY

ASYCUBE LARGO A5, THE NEW FEEDER IN THE FAMILY

Asyril has been supplying its flexible feeder range to the microtechnology industry for many years. This new product now extends the possibility to feed components up to 30 mm size.

The Asycube Largo A5 consists basically of a vibrating platform of the size of an «A5» page which can move the parts precisely on the surface. The movements are generated by means of gentle vibrations which can be controlled in frequency and amplitude. With this feature, and in combination with a camera, the feeder can quickly distribute components in an ideal position to be seized by a robot.

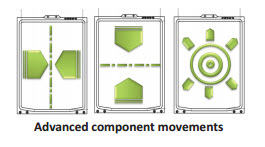

ADVANCED MOVEMENTS FOR GREATER EFFICIENCY

Due to new unprecedented movements, your parts are distributed on the surface in only three moves! In fact, two new movements allow the components present on the surface to be centred on the platform and this without falling back to a camera.

Due to new unprecedented movements, your parts are distributed on the surface in only three moves! In fact, two new movements allow the components present on the surface to be centred on the platform and this without falling back to a camera.

Thus, in less than a second, new components are ready to be gripped.

BENEFITS FOR THE CUSTOMER- a multitude of different components can be fed from the same system

- gentle vibrations which won’t degrade the quality of your components

- three degrees of freedom to precisely move the parts on the feeder surface

- possibility to structure the vibration platform (holes, grooves ...)

- minimum production changeover time

- advanced movements for even more flexibility

- intuitive configuration interface without need for programming

- Ethernet communication

- I/O to drive an external hopper or conveyor

Need an Asyril Quote?

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)