This post is brought to you by Bimba Technical Tips.

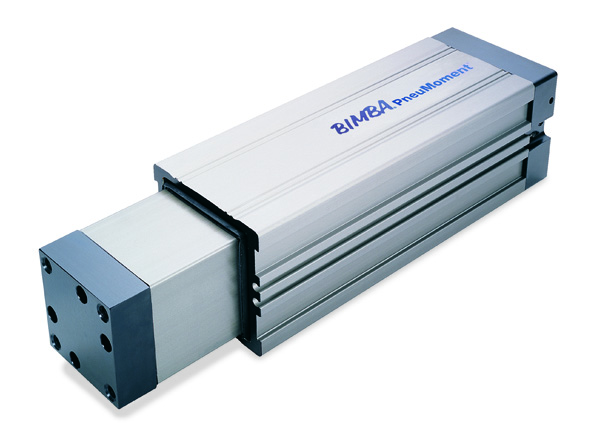

Bimba’s PneuMoment® is more than just a non-rotating actuator. It is guided, so side loads and moment loads can be handled simultaneously. It is hard coat anodized for durability, corrosion resistance, and lubricity. And its extruded exterior complements your machinery’s appearance while providing built-in switch tracks.

However, many benefits of this unique actuator are not immediately apparent:

- Designed for clean room applications

- Flexible air supply connections

- No pinch points

- Flexible mounting options

- Fits into tighter space than linear thruster

- Weighs less than cylinder with external guide rods

Clean Room Applications

In the end cap is a vacuum port. As shipped the cylinder vents through a filter installed in the port. For clean room service, or where venting is not desired, simply connect a vacuum hose to the port.

Flexible Air Supply Connections

Auxiliary ports (option R), unique to the PM, are incredibly useful. They allow air or vacuum to be supplied to the rear of the actuator and be conveyed internally to the front end cap for use by another device such as a gripper or rotary actuator. This simplifies the plumbing and eliminates hose snags, kinks, and fatigue especially in multi-axis applications.

The PneuMoment® has both end and side ports in the end cap, with plugs in the side ports. Order the Y option and we will plug the end ports instead of the side ports, no charge. The plugs can be removed and reinstalled, so no matter how it is ordered, active ports can be changed at will.

Safety

The PneuMoment® has no pinch points. In other words, there is no a way that a finger can be placed between moving parts.

For machinery that is open and accessible to operators, this is an important safety advantage. For this reason the PneuMoment® is often chosen to replace actuators with guide rods.

Flexible Mounting

Mounting can be via the base, front, or optionally via an end flange.

Built-in Stroke Adjustment

Internal stroke adjustment, available for all bore sizes except the 17 and 50, adjusts extend and retract separately. For stroke

adjustment on 17 and 50 bores use Option EB – external bumpers. External bumpers reduce noise and limit stroke, internalbumpers reduce noise only. Shock absorbers are available to absorb kinetic energy and limit stroke.