-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

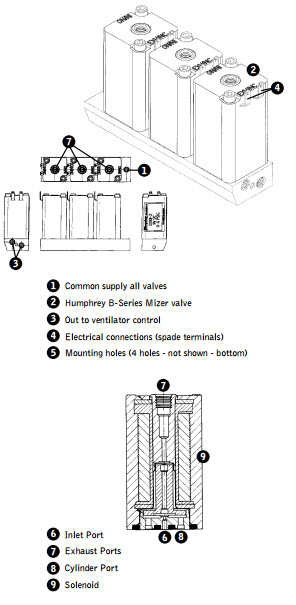

This post is brought to you by Humphrey Engineered Solutions.

Custom Manifold Assembly for Medical Ventilator Reduced Costs and Ensured Performance Throughout a Range of Environmental Extremes

Humphrey's customer's requested to provide a complete assembly that would enhance the performance of their portable medical ventilator under a wide range of environmental conditions.

THE CUSTOMER'S PRODUCT:

THE CUSTOMER'S PRODUCT:

- The customer designs and manufactures ventilators for use in respiratory therapy.

- The particular ventilator model is used in a wide range of applications.

- Customer was currently purchasing individual Humphrey valves, then manufacturing their own manifolds and assembling the system.

THE REQUIREMENTS:

- Provide a pre-assembled system that meets tight dimensional requirements

- Meet critical performance specifications

- Unit must be compatible with the company's existing controller

THE HUMPHREY ENGINEERED SOLUTION:

- Created a custom manifold with integrated electrical circuitry

- All portsand mounting holes per customer specifications

- Incorporates Humphrey's new B-Series Mizer valves

- All contact materials approved for oxygen service

- Withstands range of temperature extremes from -25º C to 49º C

- Operates at altitudes up to 10,000 feet

- Maximum power consumption 0.5 Watts

- Humphrey assembles and 100% tests all assemblies prior to shipping

THE SOLUTION:

Having an established relationship, the customer immediately saw the benefits of the Engineered Solutions approach. A Humphrey engineer was assigned to work directly with the customer's engineering department, and together they identified the opportunities to improve product performance and reduce key costs.

Humphrey met all the customer's specifications, including the physical envelope, valve performance, low current consumption and signal compatibility with their existing controller module. By awarding Humphrey the responsibility of assembling and testing each unit prior to shipping, the customer saved assembly costs, including testing costs,and ensured that its ventilator units would function properly in a wide range of physical environments.

THE PROCESS:

The Humphrey Engineered Solutions team began with the customer's request to provide a complete assembly that would enhance the performance of their portable medical ventilator undera wide range of environmental conditions. The first step was to substitute the new Humphrey B-Series valves for the original Mizer valves the customer had been purchasing individually. This would provide enhanced performance, 0.5 Watt current consumption, the ability to function in a wider temperature range (-40 to +150 F), a wide range of coil voltages, and increased coil force for more consistent actuation.

Next, Humphrey designed acustom manifold with integrated electrical circuits between the valves, common supply and exhaust galleries,and all porting and mounting holes to the customer's specifications. It was here that the Engineered Solutions team saw an opportunity to help the customer reduce costs and enhance reliability by pre-assembling the system and 100% testing each one before shipping. Now, the customer could eliminate the cost of assembling and testing units at their own facility. In addition, Humphrey's rigorous testing procedures ensured that every unit would meet the performance requirements in a wide range of environments.

Interested in a Humphrey Quote?

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)