-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

This post is brought to you by Dorner.

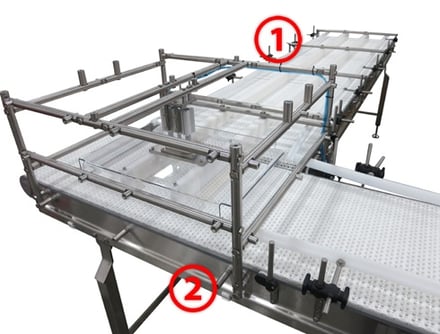

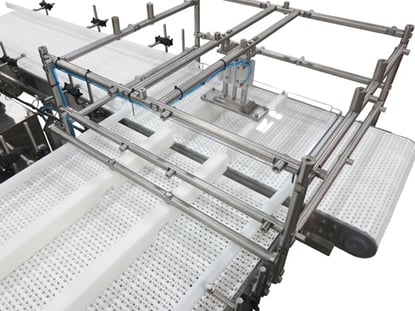

For this application, the customer needed to complete a 90 degree transfer without having the product skew. The packages are coming out of a product sealer in batches of three. They are set at a particular width spacing which we matched with specific lane guides on the first conveyor in the system.

The product travels down this conveyor onto a second conveyor and into a popup stager. The stager is there to ensure that the packages do not skew and it maintains equal spacing between products. The second conveyor is feeding into a freezer which requires the product to have a consistent orientation.

Using the photo-eye and built in timer, the pneumatic guided cylinder then lifts the stager up and allows the product to travel down the conveyor. Once the photo-eye on the second conveyor detects the products are clear, the stager is returned to loading position.

Interested in a Dorner Conveyor?

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)