-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

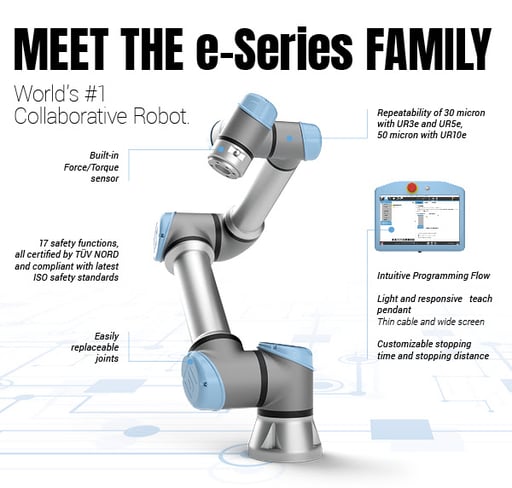

We were excited to hear the recent news that Universal Robots unveiled its new e-Series. We immediately ordered one to demo and it arrives in our offices in July. It will be a bit like Christmas morning as we unpack the box and gather the team to test this new cobot (collaborative robot).

Universal Robots has a history of solid design and quality. We expect nothing less with the e-Series and look forward to offering it to our customers. Why will the new e-Series be a smart investment? Among its numerous benefits are:

- Quick activation and deployment: under an hour to unpack, mount, and program a cobot’s first task.

- Flexibility to change its nature of work over time as production line needs change.

- A redesigned control panel for an easy user interface (for the humans that need to program and control it).

- Single phase A/C source compatibility (connect to any regular power outlet).

- 17 safety features like collision detection are built in.

- Space saving by design: compact and flexible.

- All joints are field replaceable within 2-6 minutes.

Rick Howe, President, The Knotts Company, adds, “the new e-Series Robots promise to start up faster and simpler and will offer better overall performance and features with the latest technology.”

e-Series key features that emphasize its evolution:

- New TP has a wide capacitive touch screen which is more durable. The TP cable is about 1/3 the size of the CB3 cable. Higher resolution (1280x800). TP is now much lighter.

- There is a force torque (FT) sensor built into the tool mount.

- There are additional adjustable safety settings including preventing the elbow from entering a safety boundary, stopping time, and stopping distance.

- Transitions between Normal and Reduced modes is smoother to reduce nuisanceprotective stops.

- The joints are much easier to replace.

- The safety features are all EN ISO 13849-1 Cat. 3 PLd.

- Programming is more intuitive with easier to find screens and additional guidance is provided on screen. Polyscope GUI has a completely new look and feel.

- Positional repeatability specifications are significantly improved (UR3e and UR5e 0.03mm, UR10e 0.05mm).

- A payload and COG estimator has been added (uses FT sensor).

- Process/communications speed has been increased from 125 Hz to 500 Hz providing smoother motion and improved performance. This will also increase path repeatability due to our ability to process deviations in path quicker (important for linear moves, sanding, buffing, polishing, welding…etc).

- Added RS485 serial communications on end of arm tool.

- UR5 and UR10 have high bases like the UR3.

- New waypoint concept (all stored as cartesian points).

We promise to share our impressions in a few weeks when we begin working with the e-Series. If there are any questions you’d like us to answer for you, please send a note to solutions@knottsco.com.

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)