-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

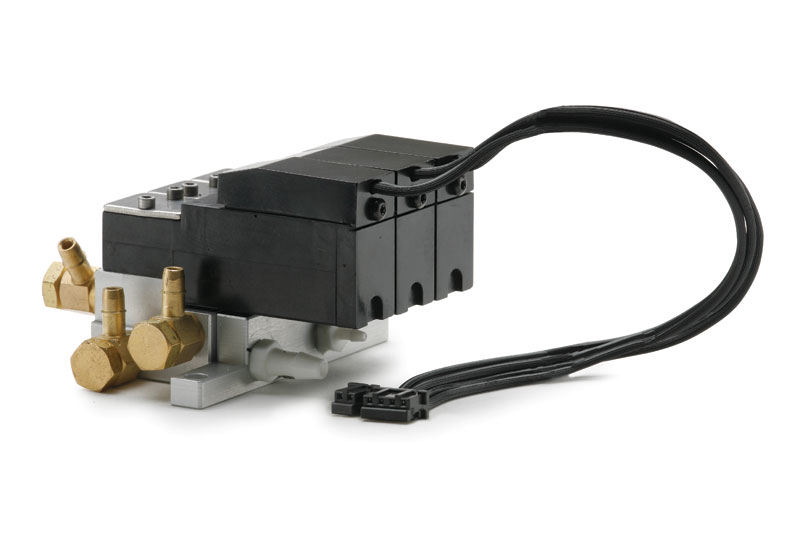

Engineering Solution - This post is brought to you by Humphrey Products.

Humphrey’s customvalve manifold met the target flow rate, spatial requirements, low current consumption and life cycle performance. This enabled the customer to create a lightweight, portable oxygen concentrator, eliminating the need to pull relatively heavy oxygen tanks with limited supply.

Customer Requirements

- Three-valve manifold assembly meeting extremely tight space and total weight requirements, with custom mounting locations.

- All valves must meet the target flow rates and have a low currentconsumption.

- The valves must meet a four million life cycle test.

- Valve assemblies to be shipped to meet an extremely short production deadline.

- Custom manifold with three HK5 diaphragm/poppet solenoid valves having virtually zero leakage.

The Humphrey Engineered Solution

- Two of the HK5 valves modified for 0.8 Watts current consumption, for overall current consumption of 3.2 Watts.

- Modified Humphrey Quick Exhaust valves with the unique shuttle design used as check valves achieved target cracking pressure of 1 PSIG or less.

- Special low profile fittings were used to reduce the overall package size.

- Valve assembly tested to six million cycles without failure.

- Tested production valve assemblies delivered to customer on time.

The Solution and Process

Working with the customer’s engineering department, the Humphrey Engineered Solutions team developed a valve manifold assembly that met all the requirements.

The three HK5 valves provided different functions. One controlled patient oxygen delivery with a sensor circuit, providing oxygen only when the patient was inhaling. The other two HK5 valves – a pressure equalization valves and a bleed valve – controlled the production of oxygen in the sieve bed, where nitrogen atoms are removed from the atmospheric air.

Since the standard Humphrey HK5 valve met the customer’s target flow rate, the only modifications were to the HK5 pressure equalization and bleed valves to reduce their current consumption. Humphrey modified their Quick Exhaust valve to function as a check valve by plugging the exhaust port and using a custom elastomer compound to achieve the target cracking pressure of 1 PSIG or less.

The customer was very familiar with the simplicity of Humphrey valves, and when the Humphrey Engineered Solutions team contacted the customer’s engineering department, the challenge was issued: Provide a low leakage valve manifold assembly that met target flow rates, current consumption, and extremely tight size and weight requirements.

As the design progressed from concept to prototype, the customer modified key flow rate specifications. Since the customer’s existing valve supplier was unable to meet those requirements, Humphrey was given the opportunity – and a very short deadline.

Working closely with the customer’s engineering department, the Humphrey Engineered Solutions team met the challenges. The first requirement was being able to adjust the internal orifice sizes in the manifold quickly to enable the customer to fine-tune the design. Then Humphrey modified two of the three HK5 valves to reduce current consumption, modified their Quick Exhaust shuttle to achieve the target cracking pressure, utilized low profile fittings to reduce the overall package size and created a custom manifold – plus delivered the 100% tested assemblies on time.

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)