-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

This is the age of nanny cams and front porch video monitoring. While one need not worry that a cobot will let the kids watch too much TV nor could it steal an Amazon package, there is much to be gained by monitoring cobots. And, we have just the tool for you!

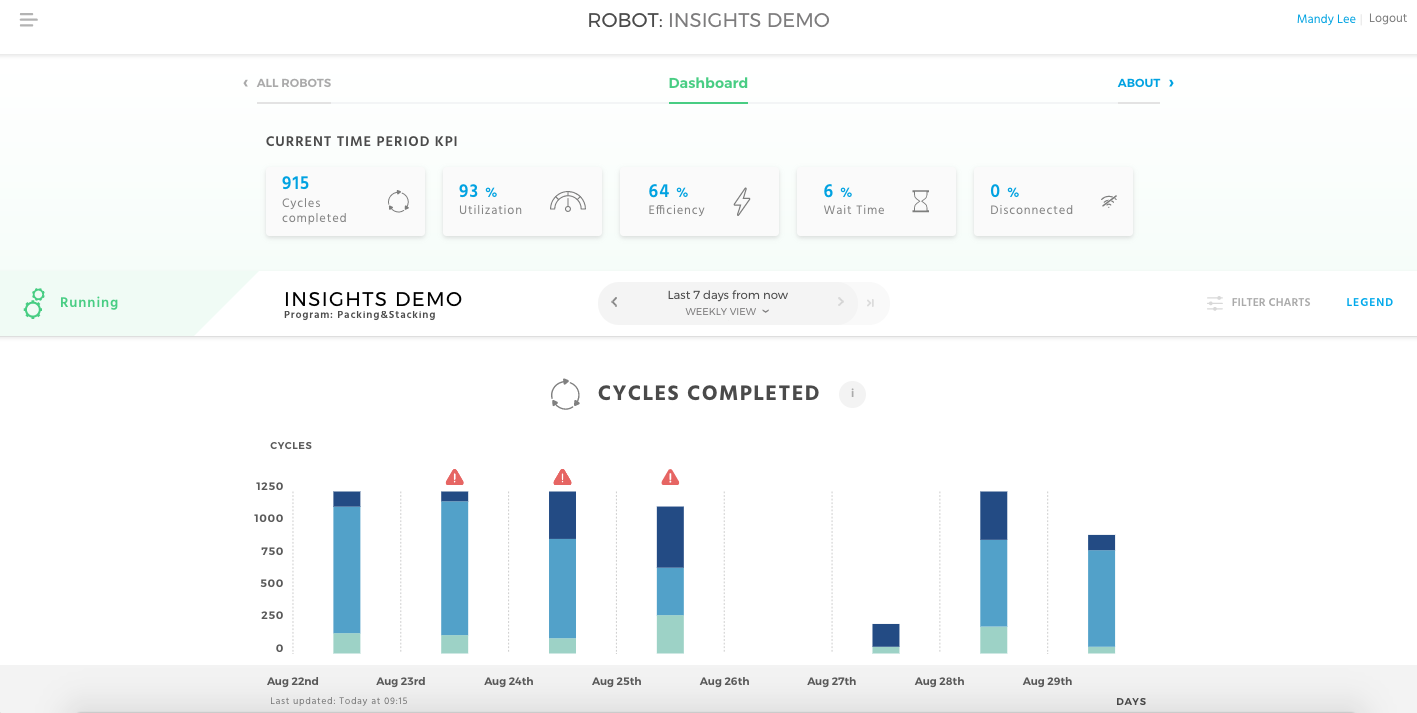

Robotiq's Insights program analyzes productivity data and sends alerts when a cobot stops. In the latter scenario, the cobot's situation can be checked quickly and most likely it can return to the production line, thus minimizing production time and financial losses.

"We have many customers using Insights and they're appreciating the immediacy of the remote alerts rather than the old method of waiting til a human walks by the cobot and notices it is not functioning. It's been an easy decision for companies to invest in this," explains Rock Howe, President of The Knotts Company.

Specifics

Insights software gives manufacturing engineers the right KPIs to improve their product quality and increase process efficiency. Automation engineers get the data to optimize robot performance by reducing cycle time and diagnosing failures. Production managers see the long term trend in robot performance to improve planning and overall productivity.

Insights Dashboard (see image below) also gives the operators real-time status and alerts to simplify the production.

- Monitors robot in real-time

- Measures robot performance over time from years to minutes

- Gives access to your robot data anytime, anywhere

- Diagnoses work cell with Digital IO states and external sensor readout

Insights is compatible with Universal Robots as well as their new eSeries. To develop a plan to bring Robotiq's Insights to your company, contact us at 908-464-4800 or solutions@knottsco.com.

Photo Credit: Robotiq

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)