A Growing Necessity for Palletizing Automation In today’s competitive manufacturing and logistics environment, companies can no longer afford to treat palletizing automation as a “nice-to-have.” Labor shortages, rising production demands, increasing SKU variability, and pressure for operational efficiency have transformed palletizing into one of the most strategic automation opportunities on the factory floor.

If you’re still relying on manual palletizing, you may be facing challenges that are slowing down throughput, driving up costs, and creating unnecessary ergonomic risks for employees.

The good news? Automating palletizing has never been simpler, faster, or more accessible—thanks in large part to turnkey, user-friendly solutions like the Robotiq Palletizing Solution.

The Critical Issues Accelerating the Need for Automation & Why Palletizing Automation Matters More than Ever

1. Labor Shortages Aren’t Going Away

Palletizing is repetitive, physically demanding, and often undesirable work. As a result, many facilities struggle to find and retain workers for this task. When positions go unfilled, production slows, deadlines slip, and labor costs rise.

Automation solves this at the root.

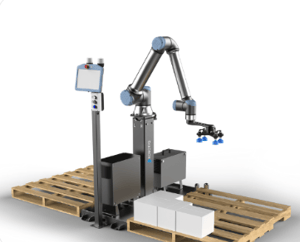

A robotic palletizer works consistently across all shifts, requires no recruitment, and never calls in sick. With tools like the Robotiq Palletizing Solution—with built-in setup assistance and intuitive software—companies can deploy automation without needing robotics experts.

2. Throughput Needs Are Increasing & Manual Processes Can’t Keep Up - WE FEEL THE NEED FOR (CONSISTENT) SPEED!

2. Throughput Needs Are Increasing & Manual Processes Can’t Keep Up - WE FEEL THE NEED FOR (CONSISTENT) SPEED!

As order volumes grow and product mixes get more complex, manual palletizing quickly becomes a bottleneck. Human workers have natural speed limits and fatigue factors, leading to inconsistent cycle times and downtime.

Automated palletizers, on the other hand, deliver predictable, scalable & consistent throughput.

Robotiq’s system integrates seamlessly with collaborative robots (cobots), enabling continuous, reliable palletizing even in space-constrained environments. With features like automatic adjustments for box sizes and easy job switching, throughput stays high—even with frequent changeovers.

3. Ergonomics & Safety Risks Are Too Costly to Ignore

Lifting, twisting, and stacking boxes all day is one of the leading causes of workplace injuries in manufacturing and logistics. These injuries result in lost-time incidents, compensation claims, and lower employee morale.

Robotic palletizing virtually eliminates these risks.

The Robotiq Palletizing Solution is designed to remove repetitive strain tasks from your employees, keeping them safe while allowing them to transition into higher-value, less physically demanding roles.

4. Quality & Consistency Matter More Than Ever

In a world of accelerated shipping expectations and lean operations, consistent pallet quality matters. Uneven or unstable pallets can cause product damage, downstream inefficiencies, and customer dissatisfaction.

Automated palletizers deliver flawless consistency.

Robotiq’s solution ensures precision placement every time, reducing errors and improving pallet stability across all SKUs.

5. Automation Today Is Faster, More Affordable, & Easier to Deploy

.gif?width=300&height=153&name=Robotiq%20Palletizing%20Configurator%20(1).gif)

Historically, automation required months of integration work and significant engineering support. But the landscape has changed.

Robotiq’s palletizing system stands out because:

-

-

It requires minimal floor space, ideal for small to mid-size manufacturers

-

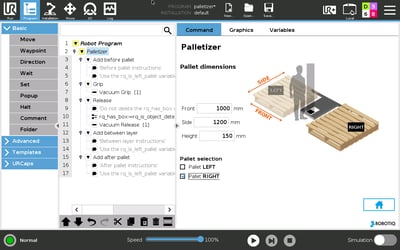

It features user-friendly, drag-and-drop programming with no coding needed

- It includes end-to-end components, from conveyor to gripper to software

- It integrates easily with UR cobots and other supported robots

This means deployment times drop from months to weeks—or even days—turning automation into a faster, more accessible investment with quick ROI.

6. Future-Proofing Your Operations Is Now a Strategic Priority

Customers expect faster delivery. Supply chains remain unpredictable. And competitors are adopting automation at accelerating rates.

Companies that automate early gain:

-

- Lower operating costs

- Increased production stability

- Greater workforce flexibility

- Better long-term scalability

Robotiq’s palletizing platform is designed with this future in mind. It can accommodate changing product lines, evolving workflows, and long-term operational shifts.

💡 Our Final Insights 💡

Palletizing is one of the highest-value, lowest-barrier entry points for automation. With the right solution, companies can eliminate labor challenges, boost consistency, protect workers, and scale their production capacity without major capital complexity.

The Robotiq Palletizing Solution provides one of the fastest and most intuitive paths to achieving these benefits, offering a turnkey system that delivers immediate and lasting impact.

INTERESTED IN EVALUATING WHERE TO START YOUR AUTOMATION JOURNEY?

Let's take that next step ..... TOGETHER!

Palletizing is a strategic move that, when done right, is a smarter, easier, and future-proof automated solution that will completely transform your business operations.

The Knotts Company & Robotiq are ready to help!

Our Knotts Automation Team would be happy to further discuss you project in detail and customize the final full-packed solution to fit your needs - at NO CHARGE!

Want to see a LIVE Automated Palletizer in operation? Come head over to our Knotts headquarters in Berkeley Heights, New Jersey, & watch a live demonstration in ACTION!

LEARN MORE HERE: https://www.knottsco.com/services/palletizing-solutions

Automated Palletizing Is No Longer Optional — Your Team of Experts at Knotts & Robotiq Can Help Make the Adoption Effortless ..... & Without the Hassle!