-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

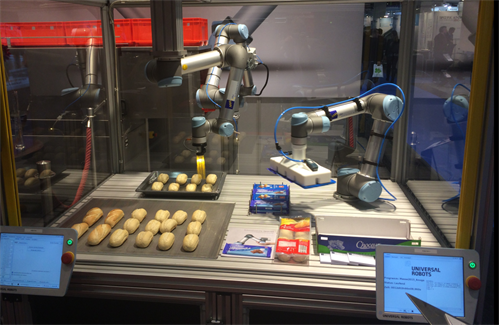

This post is brought to you by Universal Robots.

Automation is transforming the food industry with robot applications as diverse as the range of food in our supermarkets. From the first robot-run lettuce farm in the world producing 30,000 heads of lettuce a day to novel fruit-picking robotic systems capable of distinguishing between apples and oranges, productivity all along the food chain is optimized with the revolution now also reaching the work in meat packing plants. According to the U.S. Bureau of Labor Statistics, meat packing is the most dangerous job in America. It is therefore not surprising that this industry has the highest rate of fluctuation; Repetitive tasks, tiring and strenuous movements are not only an issue for those who work in the meat industry alone, but across the entire food industry.

Swedish sugar producer Nordic Sugar is one of the food manufacturers automating an especially repetitive task; three collaborating robots (known as cobots) assist in sample inspection during the main production time. They use a gripper to lift around 45,000 containers with sugar beet samples from a scale, and scan their bar-codes. Whether it is scanning, stacking eggs, spraying bread rolls or packing food in cartons: cobots are at the forefront of the food industry transformation. They become the third helping hand in production, which takes over physically demanding work and gives the staff time and space for more valuable tasks – without depriving them of their work. The personnel at Nordic Sugar are now in a position, with the use of the robot arms, to concentrate more on the area of process optimization.

Automation with cobots is an innovation which especially benefits small and medium-sized companies (SMEs). The use of robot arms like the UR3, UR5 or UR10 can be implemented economically and the small size of the robots and their simple programming allows them to be used for the most varied applications in the SME sector. The cobots enable companies to better deal with volatile markets while increasing competitiveness. The six-axis robot arms from Universal Robots are now in use globally in a wide range of industries and applications, from handling Pick-and-Place tasks to or partial process steps in the packaging branch.

In the food industry, the quality of the products and their faultless further processing and handling is especially important. The gripping of already packaged food and its preparation for transport is a matter of delicacy of touch and precision - criteria which can easily be fulfilled by lightweight cobots. At the Italian Cascina Italia company, over 2.5 million eggs have to packed every day. A UR5 robot with pneumatically controlled grippers is responsible for stacking cartons of 10 eggs each in boxes which finally contain 1,440 eggs. In this way the robot packs about 15,000 eggs per hour.

The application of cobots has also proved useful in environments with special climatic or hygienic conditions. They work in environmental temperatures between 0 and 50 degrees Celsius and function in low-oxygen environments which would require complex equipment for human staff. The machines are hermetically sealed and provided with a smooth outer housing which collects almost no dust or deposits. As a tool, the robots from Universal Robots have all the characteristics to fulfill the specific requirements of the industry.

The application of cobots has also proved useful in environments with special climatic or hygienic conditions. They work in environmental temperatures between 0 and 50 degrees Celsius and function in low-oxygen environments which would require complex equipment for human staff. The machines are hermetically sealed and provided with a smooth outer housing which collects almost no dust or deposits. As a tool, the robots from Universal Robots have all the characteristics to fulfill the specific requirements of the industry.

For everyone with an affinity for tomorrow’s technologies (today´s technology in Singapore) and would also appreciate a helping hand at home, this article is worthwhile. Lucy is definitely an interesting solution for all people needing a helping hand on the home front. And hey, if it is your birthday, the robot will also do a little jig for you.

Interested in a Universal Robots?

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)