-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

This post is brought to you by Universal Robots.

How do you make sure that a product can handle the wear and tear of an expected life cycle? - That all safety and quality standards are met? You test it. Over and over again.

Nothing is more repetitive than product testing – lending itself to one of the “3D jobs” that robots excel at: Dirty, Dangerous…and Dull.

Increasingly, collaborative robots – or cobots - are now being used for product testing. This type of automation is maximizing the testing environment, improving employee productivity and happiness, benefiting the bottom line while allowing companies to bring products to market much faster than ever before.

Take dishwashers…loading and operating a dishwasher is already a mind numbing job for a human to perform in our regular daily life –imagine trying to test how many times a dishwasher can be loaded before it wears out?

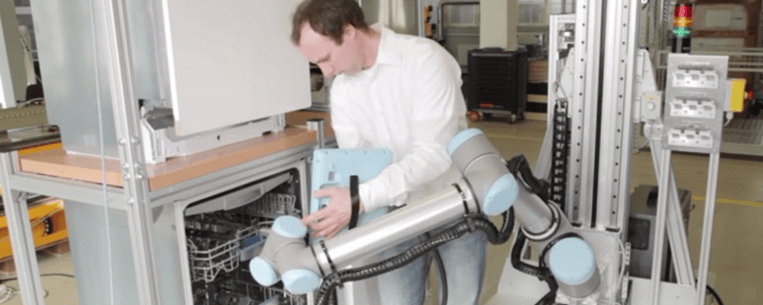

Scientists from Fraunhofer IPA in Stuttgart, Germany have now developed a mobile cobot system for Bosch Siemens Hausgeräte taking over this tedious task:

Watch how Universal Robots are programmed to load and operate dishwashers for endurance testing. From putting detergent into the machine to testing the internal baskets, the process is now automated and has delivered many benefits; Employees have been relieved of repetitive tasks and the application allows for a standardized and controlled 24/7 operation.

Moving into the Lab

The easy assembly, integration, flexibility and precision of cobots means they can be deployed to do intricate tasks including laboratory testing and analysis.

In laboratories, cobots are being used to automate demanding research projects where precision is critical. A robot can consistently and repeatedly follow exact processes and pre-defined workflows with miniscule deviation, providing optimum conditions for study and analysis. This gives scientists and researchers more time to spend on other areas of their project.

Canadian manufacturer of robotic grippers, Robotiq, demonstrates just how efficient it is to deploy a product testing solution with their 2-Finger Adaptive Gripper 85 application. From the installation of the robot and the gripper to programming trajectories, product testing and data collection, the application is easily deployed with little to no downtime in production. 3

Winning Against Chinese Competitors

Scott Fetzer Electrical Group in Tennessee uses a Universal Robots UR10 for data collection and life cycle testing of new designs. The cobot is programed to test small motors manufactured by the company, inside customer products. The robot is set to turn the product’s switch on and off, running the motor for a minute, turning it off for 30 seconds and continuing for a period of 400-hours.

During this process the cobot collects relevant data about the quality and performance of the product and the information is transmitted to data storage where it can be analyzed. This is an extremely demanding task for employees to undertake and repeat for hours on end with the same level of consistency and precision.

Director of Operations at Scott Fetzer Electrical Group, Matthew Bush said using cobots in the testing process has been a major benefit for the business.

“It’s enabled us to actually engage our customer in the testing as well; they’re excited to see us use new technology to push our design faster into production. It gives us an advantage over our competitors thousands of miles away in low-cost source countries. We’re now winning orders against Chinese competitors and bringing back work that used to be sourced in China as well.”

Interested in an Universal Robot for your business?

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)