-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

This post is brought to you by Dorner.

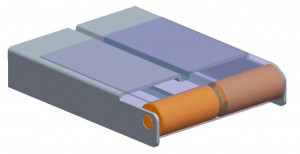

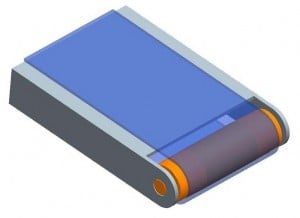

One of the largest issues of belt conveyor maintenance is belt tracking. When belts aren’t running straight on the pulleys it can cause premature wear and damage to the conveyor and belt. There are a lot of factors that can affect belt tracking such as belt splicing, pulley accuracy, or proper belt tensioning. The two most common methods of belt tracking are V-guiding and crowned pulleys.

V-guided belts have a “v” shaped plastic adhered to the back of the conveyor belt. This “v” then fits in a grove that runs the length of the conveyor and pulleys. V-guide continuously tracks the belt and keeps it running straight. For best bonding results the V-guide material, which is generally PVC or urethane, should be the same as the belt being used. Some examples of belts that cannot be used with V-guide are Teflon, polypropylene, and silicon-based belts. These belts are usually used in very specific applications such as high heat or some food applications so for most people V-guiding should work for their applications. Some pros and cons to V-guiding are:

Pros:

- Provides belt tracking along entire length of conveyor

- Multiple traction surface options

- Straight pulley provides consistent transfer for small or odd shaped products

Cons:

- Limits belting options

- Belts are not completely flat. During the bonding process the heat applied causes a small bump to form along the entire length where the V-guide is applied. This bump is very minimal and becomes less when tensioned in the conveyor. This could be a problem for small or light-weight products as it would cause them to not lay completely flat on the belt.

- Cannot be used with a knife edge transfer. Adding a V-guide to a belt makes it too large to run over such a small pulley. Typically the largest diameter pulley a V-guide belt can go over is a 1" diameter pulley.

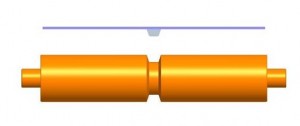

Crowned pulley tracking is a pulley with a cylindrical middle section and tapered ends. This method of tracking works by using the tapered ends of the pulley to steer the belt back to the center of the roller when it starts drifting off to the left or right. Some pros and cons to using a crowned roller are:

Pros:

- Works with most belt types. Most manufacturers assume some type of crowned pulley tracking method will be used with their belts.

- Can be used on a knife edge idler transfers

Cons:

- No control over belt tracking along the conveyor bed. The tracking only happens on the ends of the conveyor so the belt in the middle of the conveyor is free to move from side-to-side.

- Can be difficult to transfer small or odd shaped products. Although the crown of the pulley is small it can affect how odd shaped or small products are transferred because the slight tapering on the ends of the pulley.

So which tracking option is right for you? Each belt has its pros and cons making it better at some things than others. Which tracking method you choose is going to depend on your application. If you have an application that needs a knife edge transfer then a crowned roller is going to be right for you because a V-guide belt can’t go over such a small pulley diameter. A different application might call for a conveyor in a space where performing maintenance is difficult. In that scenario a V-guided belt would be good because the belt is being continually tracked as it is operating which can reduce belt maintenance.

With many of today’s conveyor applications running 24/7 it is important that maintenance times are reduced and conveyors are working properly. Having reliable belt tracking on your conveyors can help lower maintenance times and keep products moving smoothly. Whether you choose a crowned pulley or V-guide tracking method each one can ensure proper belt tracking and minimize problems associated with belt tracking.

Interested in a Dorner Conveyor?

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)