-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

This post is brought to you by Universal Robots.

Find the Right 6 Axis Robot

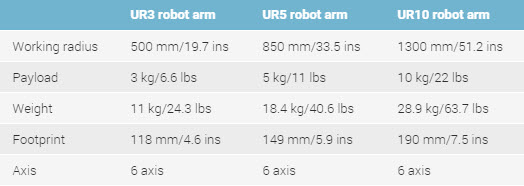

Choose between three flexible and lightweight 6 axis robot arms

Universal Robots' 3 arms are all highly flexible and lightweight 6-axis robot arms. Their 6 axis robot arms are designed to excel in a wide range of applications. The collaborative robots, or cobots, are categorized based on payload limits. The different models also have reach, weight and footprint differences.

Universal Robots' 3 arms are all highly flexible and lightweight 6-axis robot arms. Their 6 axis robot arms are designed to excel in a wide range of applications. The collaborative robots, or cobots, are categorized based on payload limits. The different models also have reach, weight and footprint differences.

What are your future robotic requirements?

You might only need a certain reach and payload today, but with the flexibility you gain with a 6 axis robot from UR, you will be able to automate much more in the future. So while a smaller robot’s reach and payload limits may meet your needs today, many of our customers find that a larger model offers better long-term flexibility. All UR robot arms are easy to move and set up for new processes and manufacturing changes. Programming is quick and easy, and programmes can be saved and accessed again for later use.

Where will you mount your robot arms?

Around 80% of the 6 axis UR robots worldwide operate with no safety guarding after initial risk assessment. Without expensive, space-consuming fencing, a 6 axis robot from UR are easy to implement virtually anywhere in your operation. Universal Robots' portable, lightweight, space-saving robots can often fit into work cells and production lines where traditional robots would not. And they can be moved and reprogrammed as often as needed.

Will your robot work collaboratively with humans?

Universal Robots are designed to work in close collaboration with humans, or by themselves. In fact, for added safety, their 3rd generation of 6 axis robots can operate in reduced mode when a human enters the robot’s work cell and then resume full speed when the operator leaves. In other set-ups, the 6 axis robot can run at full speed inside a CNC machine, and then at reduced speed when outside. Eight safety functions are monitored by our patented safety system: joint position and speed, TCP position, orientation, speed and force, as well as the momentum and force of the robot. These settings can only be changed in a password-protected area of the software.

Universal Robots are designed to work in close collaboration with humans, or by themselves. In fact, for added safety, their 3rd generation of 6 axis robots can operate in reduced mode when a human enters the robot’s work cell and then resume full speed when the operator leaves. In other set-ups, the 6 axis robot can run at full speed inside a CNC machine, and then at reduced speed when outside. Eight safety functions are monitored by our patented safety system: joint position and speed, TCP position, orientation, speed and force, as well as the momentum and force of the robot. These settings can only be changed in a password-protected area of the software.

Will you be connecting your robot to peripherals & external machinery?

All of their 6 axis robots use True Absolute Encoders that simplify integration with peripherals and external machinery. 16 additional digital I/Os make it easy to configure and connect each model. See our applications page for cases that show how flexible and adaptable our 6 axis robots are.

See the robots in action

See what the collaborative robots can do, how easy they can be programmed and how flexible they are! The Knotts Company is ready to meet with you and go over more information about Univeral Robot's 6 axis robots.

Interested in a Robot for Your Company?

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)