-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

This post is brought to you by Unitronics.

Summary:

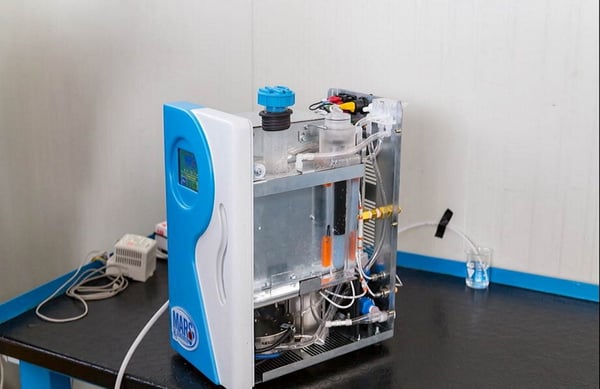

ErreDue manufactures gas production and purification equipment with a focus on accessibility and ease of use. For a new product line of Hydrogen, Oxygen, and Nitrogen micro-generators, they integrated Unitronics PLC+HMI controllers. These PLCs improved the operator experience, while offering greater functionality and reliability compared to competitors using microcontrollers.

ErreDue is an Italian company manufacturing equipment for generating and purifying gases. They offer products with the goal of enabling their customers to produce gas on site, safely and efficiently, whether in a small laboratories or a massive factory. With their dedication to easy to use products and comprehensive support, ErreDue has become an industry leader.

ErreDue is an Italian company manufacturing equipment for generating and purifying gases. They offer products with the goal of enabling their customers to produce gas on site, safely and efficiently, whether in a small laboratories or a massive factory. With their dedication to easy to use products and comprehensive support, ErreDue has become an industry leader.

ErreDue has been in the process of developing a new line of micro-generators for Hydrogen, Oxygen, and Nitrogen generation. While most of their competitors use microcontrollers on similar product lines, ErreDue wanted to use PLC control; their engineers have used PLCs in the past and liked the reliability and flexibility of PLC control. They wanted a control option that was compact without compromising usability and functionality.

“This device [Vison350], with an Ethernet port onboard, makes our generators better performing, more versatile and more innovative than our competitors’.” - Claudio D’Angelo, ErreDue

“This device [Vison350], with an Ethernet port onboard, makes our generators better performing, more versatile and more innovative than our competitors’.” - Claudio D’Angelo, ErreDue

They selected a Unitronics Vision350; this all-in-one controller offers a full-function PLC integrated with a touchscreen HMI and onboard I/O. The all-in-one approach added a lot of value for ErreDue. They were able to integrate an easy-to-use HMI panel, a powerful CPU, I/O and Ethernet and serial communications without adding a lot of bulk to their system. In addition to matching ErreDue’s physical requirements, the Vision350 also offered impeccable performance. Engineer Claudio D’Angelo raves that “this device, with an Ethernet port onboard, makes our generators better performing, more versatile and more innovative than our competitors’.” Most of ErreDue’s competitors use microcontrollers with monochrome LCD displays and membrane function keys, so the color touchscreen and function keys of the Vision350 were a major step up for the user interface and experience. Additionally, the Vision350’s robust Ethernet and RS485 communications enabled the generator to be monitored and controlled remotely, with fast and reliable data exchange.

The Unitronics Vision350 added a lot of value for ErreDue, without a lot of extra costs. D’Angelo adds “the software programming is easy and intuitive. Technical support is fast, punctual, and reliable.”

Interested in an Unitronics Product?

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)