-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

This post brought to you by Proportion Air.

Losing Steam - Figuratively and Literally

Cooking on a mass scale requires no small amount of precise engineering.

A corn tortilla manufacturer was having a problem controlling temperature with the saturated steam used to heat the cooking kettles for the corn. The manufacturer came to Proportion-Air seeking a solution.

A visit to the plant revealed the company was using a particular I to P transducer, steam valve, RTD (resistance temperature sensor), and PID (proportional-integral-derivative) loop to control the temperature. The issue arose out of a regular failure of the I to P transducer.

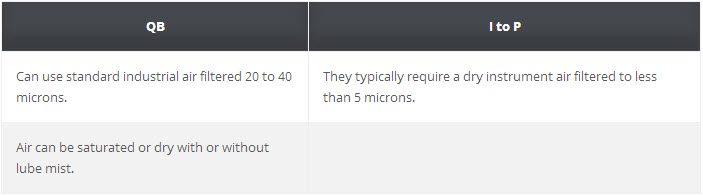

The I to P was replaced with a QB1, which is better able to withstand standard industrialair. (I to Ps require instrument air, which is defined as air filtered to less than 5 microns, and is moisture and lube free.)

Benefits of Using the QB and Steam Regulator

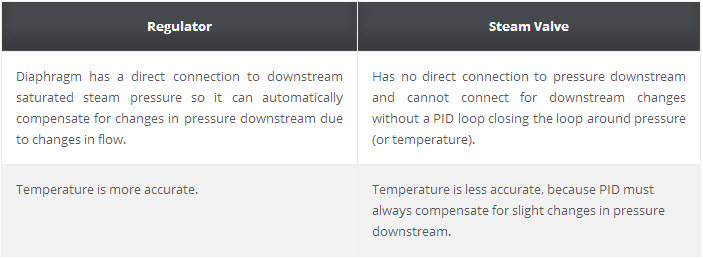

There are many benefits to using a Proportion-Air steam regulator system – specifically a Proportion-Air 0 to 60 psig QB2/steam regulator assembly – especially when compared to the operation of traditional steam valves. This assembly was installed and subsequently performed extremely well.

Since the manufacturer did not require the ultra-high accuracy of the QB2, a QB1 was substituted. And regardless of whether the QB1 or QB2 was used, the control loop did not have to work as hard because the regulator could compensate for changes on its own without the assistance of sophisticated electronic controls.

QB Series Product vs. Standard Flapper-Nozzle I to P (or E to P)

Steam Regulator vs. Steam Valve

Interested in a Proportion Air Application?

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)