-

- bimba

- Universal Robots

- dorner

- cobots

- industrial automation nj/ny

- The Knotts Company

- manufacturing

- Dorner Conveyors,

- The Knotts Co

- UR

- Robots

- PLC

- Unitronics

- automation

- automation solutions

- humphrey products

- knotts company

- cobot

- robotics

- solutions

- HMI

- conveyors

- aluminum extrusion

- aluminum extrusion in nj

- engineered solutions

- Robotiq

- air cylinder

- collaborative robots

- cost effective

- cost savings

- t-slotted extrusion

- bimba solutions

- collaborative robot

- technology

- MiR

- Humphrey

- IAI

- WAGO

- assembly

- bimba pneumatic

- machine guard

- smartflex conveyors

- solution

- 2200 Series

- cylinder

- electric cylinder

- motion control

- packaging

- pharmaceuticals

- sanitary conveyor

- Products

- automated palletizing

- automation control

- conveyor

- core competencies

- custom solution

- grippers

- palletizing

- resource

- robot

- robotics solutions

- AquaPruf

- Asycube

- Asyril

- Belt Conveyors

- Cage Clamp

- Food

- Machine Guarding

- Mobile Robots

- Norgren

- OptoForce

- Pneumadyne

- Pneumatic Valve

- ROBO Cylinder

- UR5

- actuators

- compressed air

- food safety and sanitation

- mobile industrial robot

- quality assurance

- safety

- stainless steel conveyors

- vision

- Belts

- Benefits

- Beverage

- Bimba IntelliSense®

- CT Effects

- PLC+HMI

- Predictive Maintenance

- Preventive Maintenance

- Proportion Air

- Proportional valve

- Questions

- Success

- UR10

- Vaccon

- automated inspection

- gripper

- improvement

- industrial vision

- intelligent actuator

- labeling application

- labor shortage

- life science

- medical

- medical industry

- monitoring

- pneumatic motion control

- regulator

- sales process

- sensor

- thomas

- valve

- 3200 series

- 6-axis robot

- 80/20

- Acro

- Automate

- High Pressure Regulator

- LMI

- Machine

- OnRobot

- Original Line Cylinder

- Pinch Valve

- Precision Technology

- Product News

- ROBO Cylinders

- ROI

- Reducing Costs

- automated mobile robot

- autonomous mobile robot

- connectors

- controls

- covid

- custom solutions

- customer service

- e-Series

- electric actuator

- electro-mechanical

- end of arm tools

- energy plant

- ethercat

- external resource

- flexmove technology

- guarding

- inspection

- machine control

- manufacturers

- motion

- new product

- outsource

- outsourcing

- packing

- pneumatic actuator

- pneumatic valves

- precision move

- pressure

- quick response solution

- sales tools

- steel frame

- vacuum

- vacuum technology

- welded steel frame

- 7X Series Conveyor

- AMR

- Advantages

- Application

- Applied Motion Products

- Asycube 530

- Asyfeed Pocket

- Balanced Valves

- CNC program

- Continuity Inspection Tool

- Control Panel

- Controllers

- Crowned Pulley

- F22 Series

- Factory Improved Productivity

- Filtration

- Fire Fighting

- Flexible Feed

- Freeze protection

- Gas

- IP65

- Inspekto

- IntelliPress

- Intellisense

- International Manufacturing Technology Show 2016

- LARGO A5

- Legos

- MIRAI

- Machine Controllers

- Machine Vision

- Micropsi

- NJ

- NY

- New

- New Scale Robotics

- OEE

- Oil

- Optimization

- PACK EXPO

- PC10

- Parison Blow Molding

- Pick-it

- ProControl Series

- ROEQ

- Rain Test

- Resin Block

- Rio Olympics

- SCHUNK

- Sanitation

- Sensors

- Smart Manufacturing

- Spot Welding

- TRD

- Temperature Controller

- Training

- Trio Manufacturing Technology

- Twist Clamp

- UR3

- UniStream

- Universal

- V-guide

- Valve Assemble

- Vane-Buster

- Versagrip

- Versagrip solenoid pinch valves

- Victory Actuator

- Vision430

- XTR Series

- Yamaha

- balanced solenoid valve series

- bimba electric

- bottle filling

- brewery

- brushless motor

- buna

- center point

- chicane

- cloud

- cobot compliance

- collaborative operation

- compact series

- composite cylinder

- conference

- cost

- date code

- demonstration

Get the latest in your inbox.

This post is brought to you by Intelligent Actuator

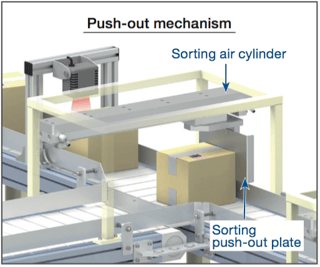

System Overview of a potential automation application.

1. Explanation of Process Cardboard boxes containing CDs travel on a conveyor. There are five different types of cardboard boxes, and each type contains different CDs. Boxes are sorted by type and transferred onto five product conveyors.

2. Explanation of Operation

- A cardboard box moves on the transfer conveyor and passes the product identification unit. The unit reads the bar code on the cardboard box and identifies the type of CDs packed in it.

- As the cardboard box arrives in front of the applicable conveyor, it is pushed by the sorting air cylinder onto the conveyor.

Problems Experienced While Using the Air Cylinder

The company was considering ways to shorten the cycle time of their automatic sorting system. The cycle time can be shortened by increasing the speed of the sorting air cylinder. However, a higher speed may cause the sorting push-out plate to bump the cardboard box and damage the products inside. This is why the company couldn’t shorten the cycle time by increasing the air cylinder speed. When they were using an air cylinder for their system, the cycle time was 5 seconds.

The company was considering ways to shorten the cycle time of their automatic sorting system. The cycle time can be shortened by increasing the speed of the sorting air cylinder. However, a higher speed may cause the sorting push-out plate to bump the cardboard box and damage the products inside. This is why the company couldn’t shorten the cycle time by increasing the air cylinder speed. When they were using an air cylinder for their system, the cycle time was 5 seconds.

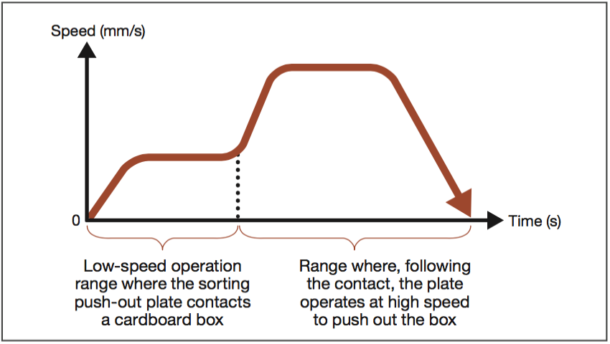

Improvements Achieved by the ROBO Cylinder

Changing the speed during movement to reduce the cycle time

The ROBO Cylinder lets you set the speed, acceleration, and deceleration separately. Using the ROBO Cylinder, the company was able to shorten the cycle time by 1 second by setting a low speed in the range where the sorting push-out plate contacts a cardboard box and setting a high speed in the range where the plate subsequently performs push-out operation.

No more damaged product

The company was experiencing occasional returns of shipped products. On checking the returned boxes, the company found damaged CD cases. The investigation of the damage cause revealed that the air cylinder of the automatic sorting system was bumping the cardboard boxes upon contact. After changing the Air Cylinder to the ROBO Cylinder, bumping stopped, and there are no more reports of damaged product.

Process Improvement with the Seven Benefits of the ROBO

- Cylinder With the ROBO Cylinder, the speed, acceleration, and deceleration can be set for each position. A stable movement is possible by setting the best speed, acceleration, and deceleration.

- You can also change the speed during movement.

Cost Cutting Effect

1. Conditions One operator oversees three lines.

| Production volume: | 8,300 boxes |

| Labor cost: | $18*/hour |

| Annual operating days: | 250 days |

2. Comparison of Air Cylinder and ROBO Cylinder

| Item | System using air cylinder | System using ROBO Cylinder |

| Cycle time | 5.0 seconds | 4.0 seconds |

| Line operating hours (day) | 11.5 hours/day Cycle time 5.0 seconds x 8,300 boxes = 11.5 hours | 9.2 hours/day Cycle time 4.0 seconds x 8,300 boxes = 9.2 hours |

| Labor cost (annual) | $17,250* 11.5 hours/day x $6*/hour x 250 days/year = $17,250* | $13,800* 9.2 hours/day x $6*/hour x 250 days/year = $13,800* |

Note: One operator oversees three lines, so the labor cost per hour is calculated as $18* / 3 lines = $6*.

3. Cost Cutting Effect

| Air cylinder | ROBO Cylinder | ||

| Labor Cost (annual) | $17,250* - | $13,800* = | $3,450* |

| Difference = | $3,450* |

Result

Interested in Learning More?

Please fill out our contact form, and a member of the Knotts Team will get in touch to help you.

%202.png?width=323&height=215&name=PH_VA_VR_Series_Technical_Support%20(1)%202.png)